What are The Types of Manufacturing Processes

Amorphous lumps of material are turned into the everyday products through several manufacturing processes. In this article we are going to discuss about six different types of manufacturing processes, in which five of them are traditional manufacturing process and the sixth one is a modern process. These processes are essential for the production of desired product.

But before we discuss about the manufacturing processes lets

discuss what is a manufacturing process.

What is a manufacturing process ?

Manufacturing process simply refers to the process manufacturing

of goods in large quantities using machines. It is concerned with people who

have discipline in working and have a large number of machinery, equipments and

tools with different automations required for a particular job.

It requires work discipline to participate in a manufacturing

process. The worker must have required experience and knowledge about the

machinery and tools to properly do the job without causing any troubles and

delay.

Six Types of Manufacturing Processes

There are six main categories of manufacturing processes. Each

one of these categories contains a large number of different manufacturing

techniques.

- Forming

- Casting

- Molding

- Joining

- Machining

- Additive manufacturing

Let’s look through each of the six categories in detail.

Forming

Forming involves applying forces or pressure and plastically

deforming the material to produce the desired shape. Forming is typically used

for metals. Most forming processes can be done when the metal is either above or

below its recrystallization temperature.

This is simply known as hot or cold working.

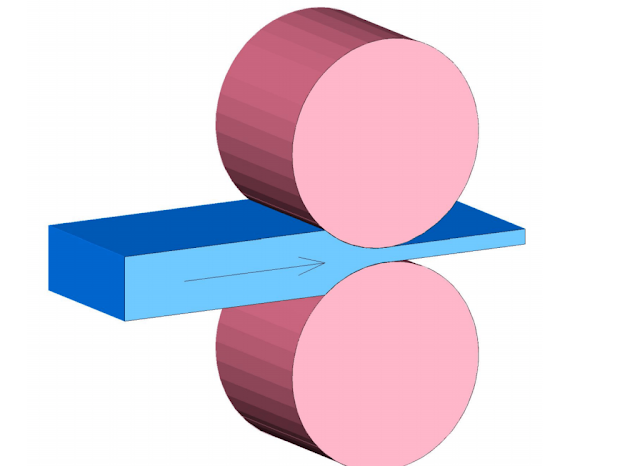

|

| Rolling process |

Hot working makes it is easier to plastically deform the metal.

But cold working causes strain hardening resulting in increases of strength of

the material.

Three common forming processes are

- Forging

- Rolling and

- Extrusion.

During impression forging, the metal is placed between top

and bottom closed dies. Repeated hammering strokes cause the metal to flow into

the shape of the dies. Compared to objects which are cast objects produced

using forging can have improved mechanical properties. But it can be difficult

to achieve tight tolerances using forging, and the required equipment can be

expensive.

Extrusion is a continuous process which involves placing hot metal in a chamber and using a ram to force it through a die, producing a long object with a constant cross-section. This process provides an excellent surface finish and can achieve very tight tolerances. The main downside of this process is that it is only suitable for producing two-dimensional shapes.

Rolling is probably the most commonly used forming process. It

involves passing metal between two or more rollers which apply pressure and

reduce thickness. Products such as I-beams can also be manufactured by rolling.

It can result in improved mechanical properties. Rolling is good for large

scale production due to its automation capability. But it can’t be used to

produce very complex shapes.

The next manufacturing process is casting.

Casting

Casting involves pouring molten metal into a mold and

allowing it to solidify. This is called as a primary shaping process. To

achieve the desired surface finish a secondary process such as machining is

typically needed. Like forming, casting is also most commonly used for metals.

There are three common types of casting are

- Die casting

- Sand casting, and

- Investment casting

In die casting, molten metal is forced into reusable metal

dies at high pressure. Once the metal has solidified, it is removed from the

mold.

Die casting is mostly used for non-ferrous metals like

aluminum and zinc, which have low melting temperatures. It provides an

excellent surface finish, and can achieve very tight tolerances. The start-up costs

tend to be high, so it is only really suitable for large production runs.

In sand casting, a pattern is used to create a single-use

mold from damp sand. The sand is typically contained in two mold boxes called

the cope and the drag. Molten metal is poured into the mold through a channel

formed in the sand. When the metal has solidified the cast object can be

removed from the sand. Sand casting can be used for a wide range of metals, including

those with high melting temperatures. It can produce large and complex parts,

and initial costs are very low, making it good for small production runs. However

it provides a poor surface finish, and is not as accurate as other casting

processes.

In investment casting several wax patterns of the same object

are created and attached to a sprue. The wax tree is dipped into a slurry to

create a ceramic mold. Then heat is applied to melt out the wax.

Molten metal is then poured into the ceramic mold, and once

the casting has cooled the mold is broken off. This process is good for parts

with complex geometry, and can achieve tight tolerances. But it is an expensive

and time consuming process.

Molding

Molding is very similar to casting. It involves shaping a liquid or pliable material using a mold. Molding is generally used for forming plastics. Typical molding processes are injection molding, compression molding and blow molding.

Injection molding is mostly used for thermoplastics, which

are polymers which soften when they are heated and harden when they are cooled.

It is a very fast process, and can be fully automated, meaning labor costs are

low. But initial costs are very high, due to the expensive molds hence its only cost-effective

for large production runs.

Compression molding involves pouring a definite amount of

material into a mold. The mold is closed and pressure and temperature are

applied. Compression molding is mostly used for thermosets materials. Thermosets

are polymers which irreversibly harden when heated. Although the tooling costs

are relatively cheap, which makes it good for small production runs, but it is

quite a slow process and is not well suited for complex designs.

The manufacturing that we have discusses so far are material deformation

processes.

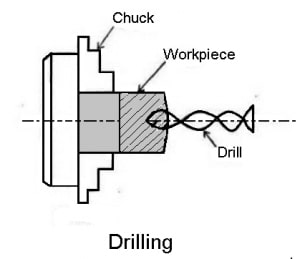

Machining

Machining is a material removal process. It an important part

of a manufacturing process. A tool is used to remove material from a larger

object. It is often used for secondary shaping, when the part has already been

formed using a primary process like casting molding.

Machining can be used for a wide range of materials,

including metals, plastics and wood. Examples of machining include drilling,

turning and reaming.

Drilling is the cutting of a normal circular hole by pressing

a rotating drill bit through a solid object.

Turning is the use of a cutting tool to shape a rotating

workpiece.

To learn more about machining click here

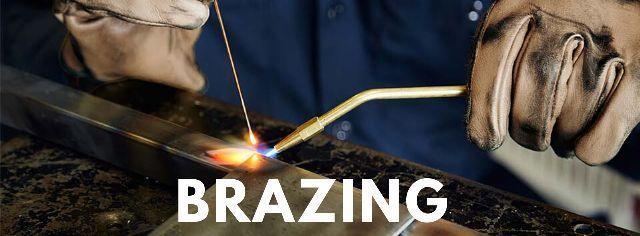

Joining

Joining involves combining multiple separate components into

a larger assembly. Like machining, joining is a secondary process.

Some examples of joining processes are welding, riveting,

brazing, soldering , fastening etc. Welding uses extremely high heat to fuse

distinct metal parts together. Unlike soldering and brazing, the base metal melts

during welding. The final category is Additive Manufacturing, which involves

adding material to build up the desired object, typically one layer at a time.

Read the differences between brazing and soldering

Additive manufacturing techniques

It is a modern manufacturing process. 3D printing, selective

laser sintering and vat polymerization are some examples of additive

manufacturing techniques.

For 3D printing a computer is used to successfully build up an object layer by layer. 3D printing is a slow process and the range of materials which can be used is limited. It tends to be used for prototyping rather than for mass production.

That’s it for this introduction to manufacturing processes! Please

leave a comment to let me know what you think!

![6 Important Types of Manufacturing Processes [2023]](https://1.bp.blogspot.com/-sZrglaSD4jY/YLB6vAGaqII/AAAAAAAAA6o/kfRvJT0AcAUeSp-4_YXZbjFTEu0YHt14ACLcBGAsYHQ/w100/types%2Bof%2Bmanufacturing%2Bprocesses.jpg)

![All Lathe Machine Operations [2023]](https://1.bp.blogspot.com/-x39Kvjg7HZA/X19vz4qAfrI/AAAAAAAAAq8/xkgD4fxHPOkTTJ8ltx6OE_wyN-1PJWRXgCLcBGAsYHQ/w100/Lathe%2BMachine%2Boperations.jpg)

0 Comments